описание продукта

WHB of Smelting

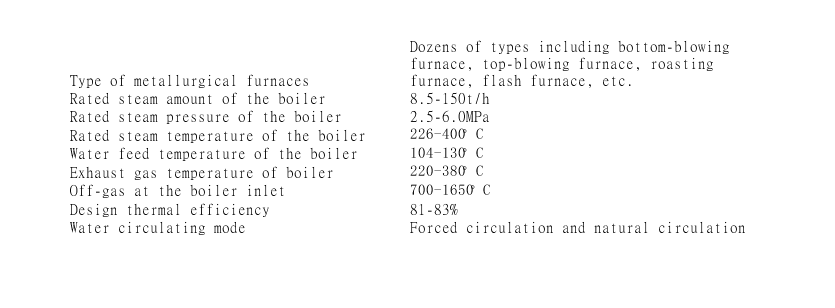

Waste heat boiler (WHB) of nonferrous metal smelting is a piece of equipment which uses the waste heat generated in the process of nonferrous metal smelting (such as waste heat of flue gas, chemical reaction, combustible waste gas, waste heat of high-temperature products, etc.) as the heat source to obtain steam or hot water with a certain pressure and temperature. WHB is an important equipment for waste heat recovery and utilization, which plays a very important role in improving energy efficiency and saving fuel.

Типоразмерный ряд:Used in bottom blowing furnace, reduction furnace, side blowing furnace, rotary kiln, boiling roasting furnace, blast furnace, reflection furnace, electric furnace, flash furnace, fuming furnace, coking furnace, rotary furnace, AUSMELT furnace and other furnaces, with the maximum steam output of 150t/h, the highest steam parameter of 6MPa, 400°C.

Типоразмерный ряд:Used in bottom blowing furnace, reduction furnace, side blowing furnace, rotary kiln, boiling roasting furnace, blast furnace, reflection furnace, electric furnace, flash furnace, fuming furnace, coking furnace, rotary furnace, AUSMELT furnace and other furnaces, with the maximum steam output of 150t/h, the highest steam parameter of 6MPa, 400°C.

Производительность:One 1 million t/a top blown nickel smelting furnace and one one 400,000 t/a copper flash furnace can be supported to the largest capacity.

Производительность:One 1 million t/a top blown nickel smelting furnace and one one 400,000 t/a copper flash furnace can be supported to the largest capacity.

Область применения:Carry out a comprehensive and careful inspection before the the using of WHB, especially, for the important parts and important components are the key area needing inspection and deal with any issues that are found promptly; Boiler feed water needs softening treatment; move the boiler safety valve to the proper position beforehand.

Область применения:Carry out a comprehensive and careful inspection before the the using of WHB, especially, for the important parts and important components are the key area needing inspection and deal with any issues that are found promptly; Boiler feed water needs softening treatment; move the boiler safety valve to the proper position beforehand.

Контактный телефон+86 13521339794

Контактный телефон+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Преимущества и особенности

The WHBs for lead, zinc, copper, nickel and tin smelting developed solely by ENFI can effectively solve the difficult problems such as ash deposits, slagging, corrosion and wear;

The WHBs for lead, zinc, copper, nickel and tin smelting developed solely by ENFI can effectively solve the difficult problems such as ash deposits, slagging, corrosion and wear;

Have the advantages of multiple supporting furnace types, wide application range, high reliability and good economic benefits;

Have the advantages of multiple supporting furnace types, wide application range, high reliability and good economic benefits;

WHB, as one of core expertise of ENFI, has more than 20 independent intellectual property rights patents in structural design, forced circulation, thermal calculation, control system, dust removal equipment and other key technologies.

WHB, as one of core expertise of ENFI, has more than 20 independent intellectual property rights patents in structural design, forced circulation, thermal calculation, control system, dust removal equipment and other key technologies.

Принцип работы

A series of innovative technologies are applied in designing the waste heat boiler equipment, inside which, the waste heat of high temperature smelting flue gas is recovered by using deoxygenated water, meanwhile, full-time constant pressure regulating technology and mixed water recycling technology are applied which can effectively eliminate corrosion caused by flue gas, smoke dust depositing and slagging, adapt to the frequent fluctuation of smelting process load, guarantee safe and stable operation of the boiler, achieve energy conservation and emissions reduction in the non-ferrous industry.

Технические параметры

Достижения применения